In the world of critical power systems, ensuring reliability is paramount. While backup generators and UPS systems are designed to provide power when the grid fails, their dependability can only be guaranteed through rigorous, real-world testing. The most fundamental and widely used tool for this essential task is the resistive load bank.

But what exactly is a resistive load bank, and how does this crucial piece of equipment work to verify the performance of your most critical power assets? This technical deep dive will explain the science behind resistive load banks and their indispensable role in power system testing.

What is a Resistive Load Bank?

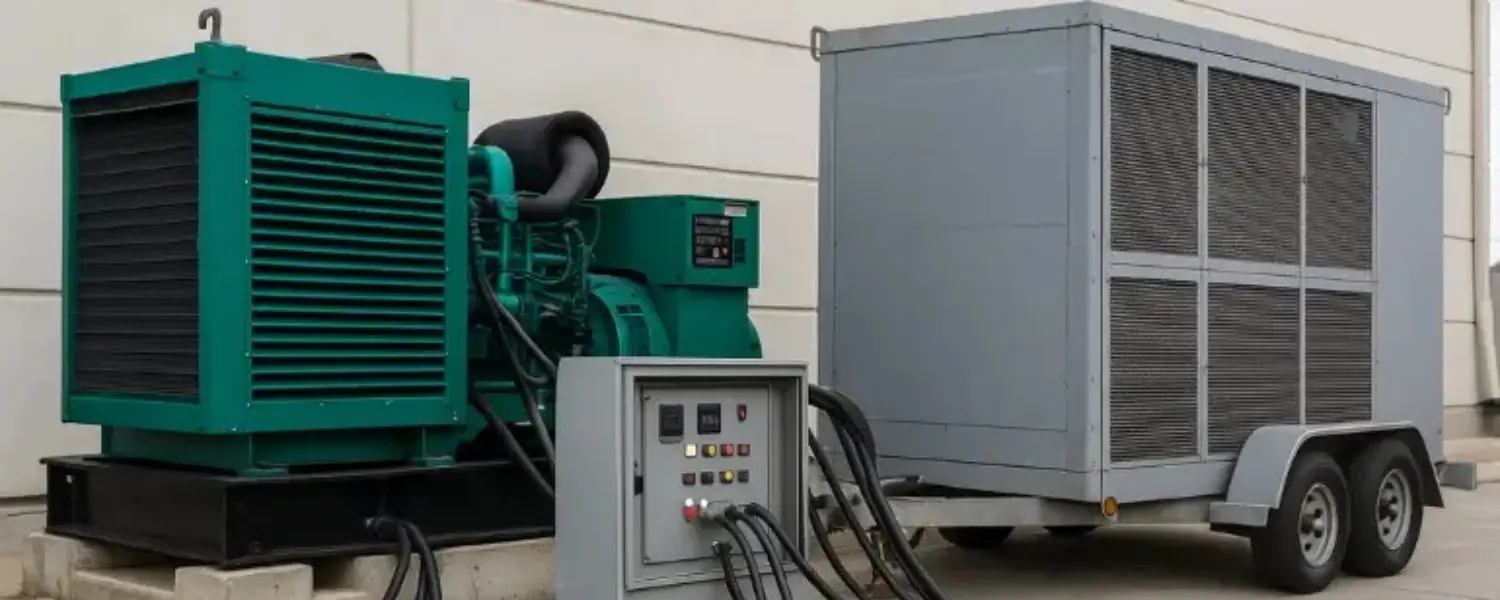

At its core, a resistive load bank is a device that simulates a “real power” electrical load. It is designed to test a power source, like a generator, by drawing a precise amount of current and converting that electrical energy into heat. Think of it as a giant, highly sophisticated, and controllable heating element.

The primary purpose of a resistive load bank is to apply a specific kilowatt (kW) load to a power source, mimicking the real-world demand of equipment with purely resistive loads, such as lighting systems and heaters. This allows technicians to test the power source’s capacity, stability, and endurance in a safe, controlled environment without risking the facility’s live, sensitive equipment.

How Do Resistive Load Banks Work? The Technical Breakdown

The operation of a resistive load bank is based on a straightforward principle of physics: the conversion of electrical energy into thermal energy. This is achieved through three primary components working in unison:

The Resistor Elements: The heart of the load bank is a set of large, high-power resistors. These components are specifically designed to resist the flow of electrical current. When the load bank is connected to a power source and activated, electricity flows through these resistors. According to Ohm’s Law, this resistance causes a voltage drop, which in turn generates a precise and measurable electrical load.

The Cooling System: The energy conversion process generates an immense amount of heat. To prevent the resistor elements from overheating and failing, resistive load banks are equipped with a powerful cooling system, typically consisting of one or more high-velocity fans. This forced-air cooling system continuously draws ambient air across the resistors, safely dissipating the heat into the atmosphere.

The Control System: A sophisticated control system allows the operator to apply the load with precision. This is often done in incremental steps (e.g., 5 kW, 10 kW, 50 kW), allowing for a gradual increase to the power source’s full capacity. Modern resistive load banks feature digital controls that enable automated test cycles and real-time data logging of key parameters like voltage, current, and frequency.

The Power Factor of Unity: A Defining Characteristic

A key technical characteristic of a resistive load bank is that it creates a load with a power factor of 1.0, or “unity.” Power factor describes the relationship between real power (kW), which does the actual work, and apparent power (kVA), which is the total power supplied.

A unity power factor means the current and voltage waveforms are perfectly in phase. In practical terms, this signifies that a resistive load bank draws only real power (kW) from the source. For a 100 kW resistive load, the generator must produce exactly 100 kW of real power and 100 kVA of apparent power. This makes it the ideal tool for testing the prime mover (the engine) of a generator set, as it directly tests its ability to produce raw horsepower.

The Critical Applications of Resistive Load Banks

The simplicity and effectiveness of resistive load banks make them indispensable for several critical applications:

Generator Commissioning and Maintenance: They are the industry standard for testing newly installed generators to ensure they meet their nameplate specifications. They are also used for routine annual testing to verify the ongoing health and reliability of standby power systems.

Preventing Diesel Engine Wet Stacking: This is one of the most important uses for resistive load banks. When diesel generators run for long periods under light or no load, they don’t reach their optimal operating temperature. This leads to a harmful buildup of unburned fuel and soot in the exhaust system, known as wet stacking. Applying a full load with a resistive load bank brings the engine to its proper temperature, burning off these deposits and keeping the engine clean, efficient, and reliable.

UPS and Battery System Testing: They are used to perform discharge tests on Uninterruptible Power Supply (UPS) systems and battery banks. This verifies the health and true capacity of the batteries, ensuring they can support the critical load for the required duration during an outage.

Frequently Asked Questions (FAQ's)

Q. What is the main difference between a resistive and a reactive load bank?

A resistive load bank tests the “real power” (kW) of a source and has a 1.0 power factor, simulating loads like heaters. A reactive load bank tests the “apparent power” (kVA) and can simulate loads with a power factor less than 1.0, such as motors and transformers.

Q. Why is a 1.0 power factor important for resistive load banks?

A 1.0 power factor means the load bank is testing the power source’s ability to produce pure, usable power (kW) without any reactive load. This makes it the perfect tool for testing the raw horsepower and performance of a generator’s engine.

Q. How does a resistive load bank prevent “wet stacking” in diesel generators?

By applying a full electrical load, a resistive load bank forces the diesel engine to work hard and reach its optimal operating temperature. This high temperature is necessary to completely burn off fuel and soot deposits in the exhaust system, preventing the harmful buildup known as wet stacking.

Q. Can I use a resistive load bank to test a UPS system?

Yes, resistive load banks are commonly used to perform discharge tests on UPS systems. This test verifies the health and capacity of the batteries, ensuring they can provide the required backup power for the specified duration.

Q. What are the key components inside a resistive load bank?

The three main components are the resistor elements (which create the electrical load), a powerful cooling system (typically fans to dissipate heat), and a control system (to apply and adjust the load precisely).

Q. How is the immense heat generated by a resistive load bank managed?

The heat is managed by a powerful forced-air cooling system. High-velocity fans continuously draw ambient air over the hot resistor elements and safely exhaust the heated air into the atmosphere, preventing the unit from overheating.

Q. Is resistive load bank testing required for brand-new generators?

Absolutely. It is a critical part of the commissioning process. Testing a new generator with a resistive load bank is the only way to verify that it performs according to the manufacturer’s specifications and can handle its full rated load before it is put into service.

Q. What information should a test report from a resistive load bank include?

A comprehensive test report should include key data points like the applied load in kW, the stability of the voltage and frequency (Hz) at different load steps, engine oil pressure, and coolant temperature, along with the duration of the test.